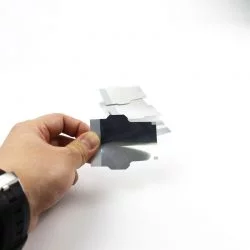

The Polyethylene (PE) materials have good flexibility and compression resistance, but its tensile resistance is poor. has white and transpatent colors. can do metallization process. often used in the bottles with frequency pressing and easy deformation. But PE material is too soft, needs to increase stiffness by increasing the thickness, 80 ~ 100μm thickness of the most common, often with bigger area of labeling materials.

RENYI can provide white, clear and silver color.

| Product No. | CCPEW085 | CCPET085 | CCPES085 |

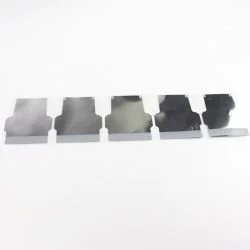

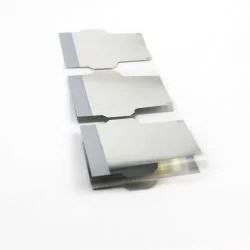

| Facestock | White polyethylene film | Transparent polyethylene film | Bright silver polyethylene film |

| Thickness | 85 g/m2, 0.085 mm | 80 g/m², 0.085 mm | 80 g/m², 0.085 mm |

| Adhesive | acrylic based adhesive | acrylic based adhesive | acrylic based adhesive |

| Liner | White glassine paper 61 g/m2, 0.055mm | White glassine paper 80 g/m², 0.070 mm | White glassine paper 61g/m2, 0.055mm |

| Color | White | Clear | Bright silver |

| Service Temperature | -29℃-93℃ | -29℃-93℃ | -29℃-93℃ |

| Application Temperature | -5°C | -5°C | -5°C |

| Printing | Full Color | Full Color | Full Color |

| Features | The corona treated face material can be printed by letterpress, flexo, and silk screen, giving good print results with UV curing and water based inks. | To ensure optimum wettability and ink bond, additional in-line corona treatment is required. | Sharp film tooling preferably in flat-bed, are important to ensure smooth conversion. Acceptance of hot stamping foil is excellent. Need avoid too much re-winding tension to causing bleeding. |

| Size | Customized | Customized | Customized |